Why do leading global brands choose EVA foam?

2025-02-15

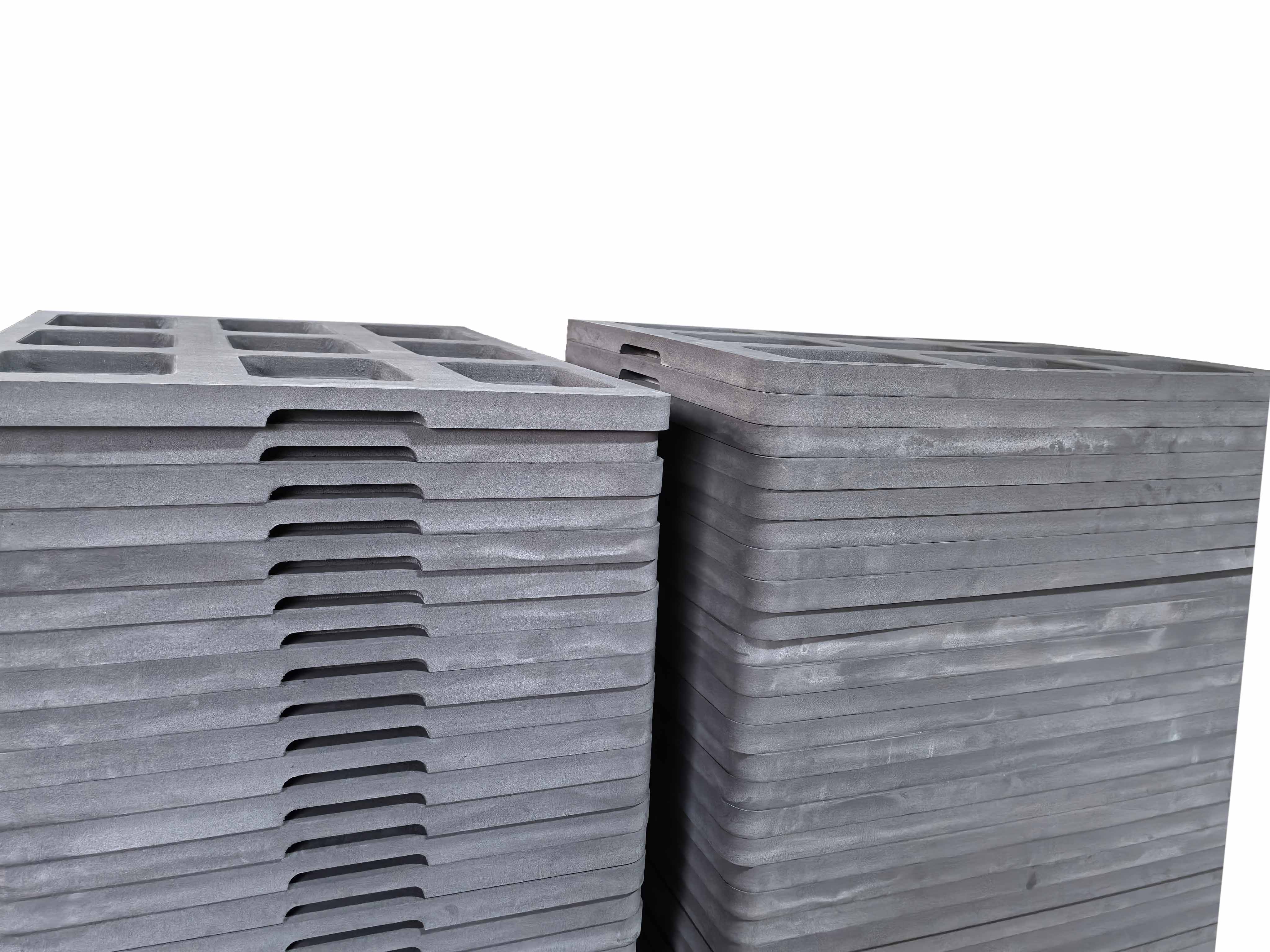

In today’s industrial manufacturing and consumer goods sectors, the choice of materials directly impacts product performance, safety, and user experience. As a high-tech enterprise specializing in the research, development, and production of EVA foam (ethylene-vinyl acetate copolymer), Fubo Company continuously provides customers with solutions that combine functionality and environmental friendliness, leveraging its deep expertise in materials science and precise insight into market demands. Below, we will explain why EVA foam is the optimal choice, based on its core advantages.

Six Core Advantages of EVA Foam

Outstanding Cushioning and Shock Absorption Performance

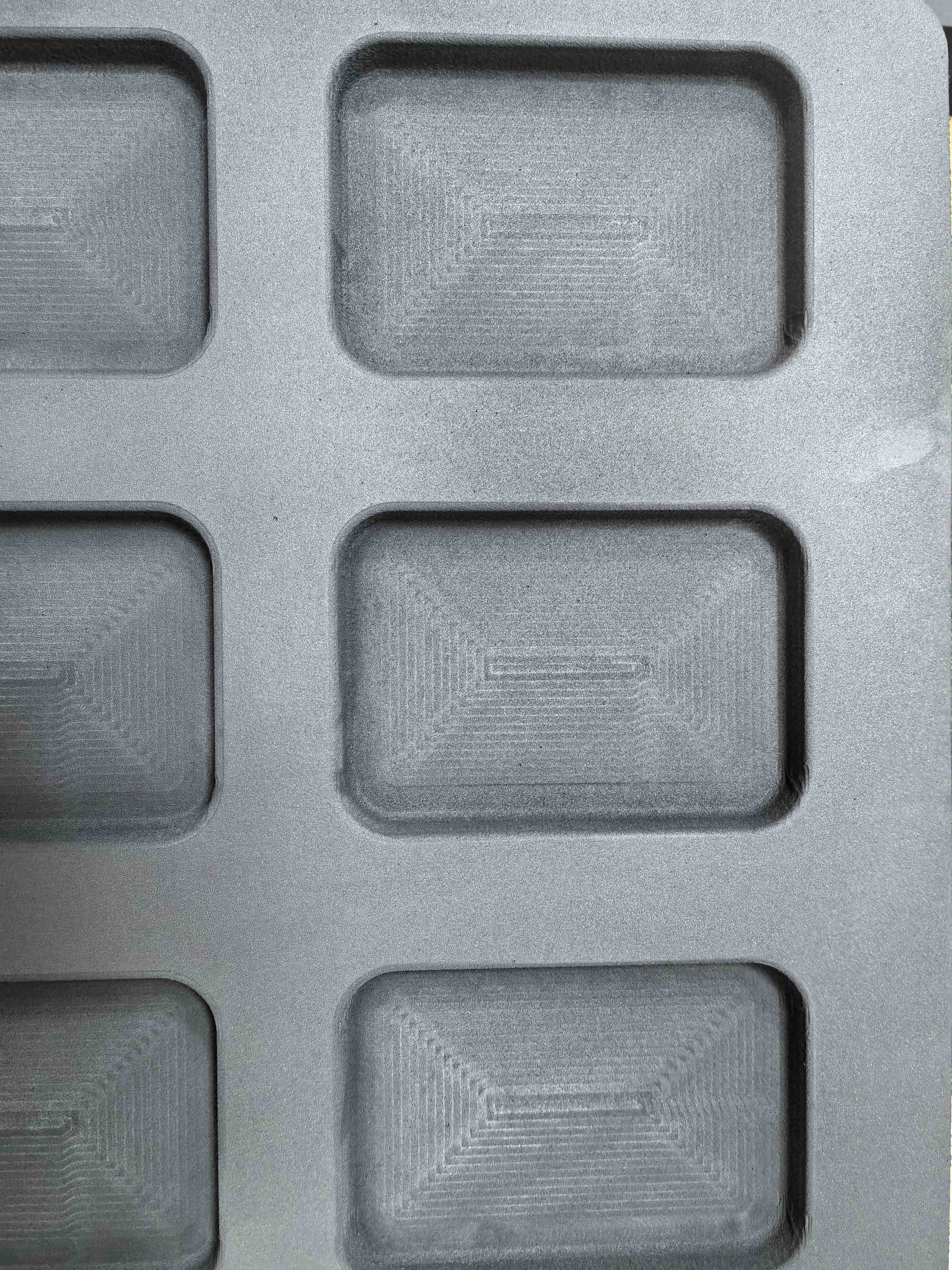

EVA foam has high resilience and energy-absorbing characteristics, effectively reducing impact forces to protect sensitive electronic products, medical devices, fragile items, etc., from damage during transport or use. It is an ideal material for packaging, sports protective gear, and other fields.

2. Lightweight and High Malleability

With a density of only 0.03-0.15g/cm³, EVA foam is both lightweight and strong. It supports various processing techniques, including die-cutting, heat pressing, and carving, enabling customization of complex shapes and irregular structures to meet the needs of different industries.

3. Weather Resistance and Chemical Stability

EVA foam is UV resistant, stable across a wide temperature range (-60°C to 80°C), waterproof, moisture-resistant, and corrosion-resistant, making it suitable for outdoor equipment, automotive parts, and other harsh environments.

4. Environmental Safety and Compliance with International Standards

Non-toxic and odorless, EVA foam meets various certifications such as RoHS, REACH, and FDA, ensuring compliance with food-grade contact and children’s product safety requirements. This helps customers address global green supply chain challenges.

5. Excellent Acoustic and Thermal Insulation Properties

With its closed-cell structure, EVA foam effectively blocks sound transmission and heat exchange, making it widely used in building soundproofing, thermal insulation for new energy batteries, and other fields.