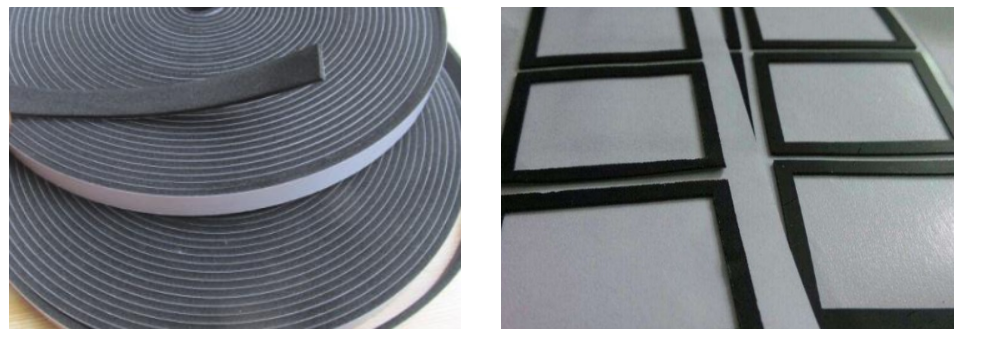

EVA shaped foam is used in the screen shock absorber industry

2025-02-15

Recently received a sample customization project, military notebook waterproof, anti-static protection EVA. Speaking of notebooks, you may think of Lenovo, Acer, SONY and other brands that we usually use. These are commercial laptops, but military laptops are different. This kind of notebook requires the MTBF of the product to reach how long, the product's EMC, safety regulations, and environmental temperature must meet certain national or international standards, referred to as the national military standard GJB or the United States military standard.

And this EVA foam lining is mainly used in military notebooks where? The notebook itself has a screen, and the screen needs to be fixed on the top cover, and there must be a layer of EVA in the middle, which needs to be shock-proof, waterproof, anti-static, and the environmental high and low temperature need to support the requirements of -40-60. This plays a key role in the material and stability of EVA itself. To get this client. Fubo Packaging Engineering Department selects the best quality EVA material, super A material, and adopts imported 3M glue for gluing.

The first step is to measure the anti-static index of EVA with a tool. After measurement, the level of 9 is passed.

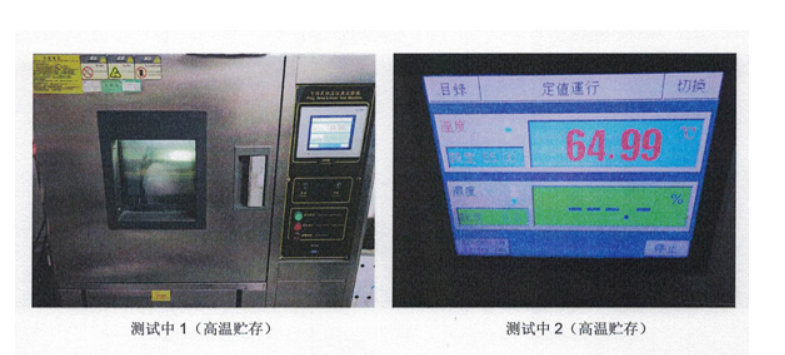

The second step is to test the high temperature of raw materials. Because military notebooks work outdoors for a long time, the temperature can reach 4/50 degrees. If EVA is used for a long time, it is possible to fall off and melt. Fubo Engineering Department uses an environmental high and low temperature box to first store the overglued EVA at room temperature for 4H. Why store 4H is to ensure full penetration of various raw materials inside the overglued EVA, and then it is heated to 60 degrees to paste it on the screen and shell. Let the hardened notebook run for 48H to see the viscosity of rubber EVA, waterproof. The temperature is adjusted to 65 degrees, which means that the environmental chamber may have an error of plus or minus 5 degrees. After 48H test, the screen and shell are treated with water drop and external force. No water leakage or melting was found.

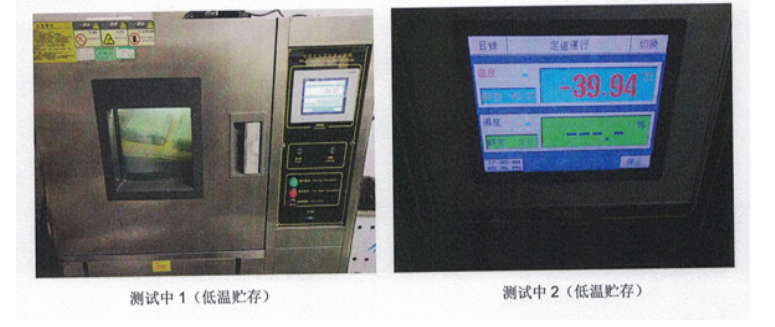

The third step, the high temperature has passed, and now the low temperature needs to be tested, because the reinforced notebook is also called a portable notebook, which will be used in all various areas, in the GJB, the low temperature needs to be tested to -40 degrees. In the same way, the glue EVA is stored and tested at low temperature. After 48 hours of storage and operation, no water leakage, melting and other phenomena were detected in the glued EVA.

After anti-static, waterproof, environmental high and low temperature tests, this EVA meets some technical specifications and requirements of GJB. Immediately according to the customer size to open the mold design sample. After about 1 week of experiment, debugging, sample, to provide military customers with a satisfactory customized EVA solution. The implementation of this project has laid a solid foundation for Fubo Packaging to enter the localization and military industry. Fubo packaging from product development, design, production, to provide customers with a complete set of solutions.