±0.1mm precision · 0.3% defect rate: Fubao Company reshapes the benchmark of EVA foam manufacturing with its full industry chain R&D.

2025-02-15

±0.1mm Precision · 0.3% Defect Rate: Fubo Company Reshapes the Industry Benchmark forEVA Foam Manufacturing with a Full-Chain R&D Model

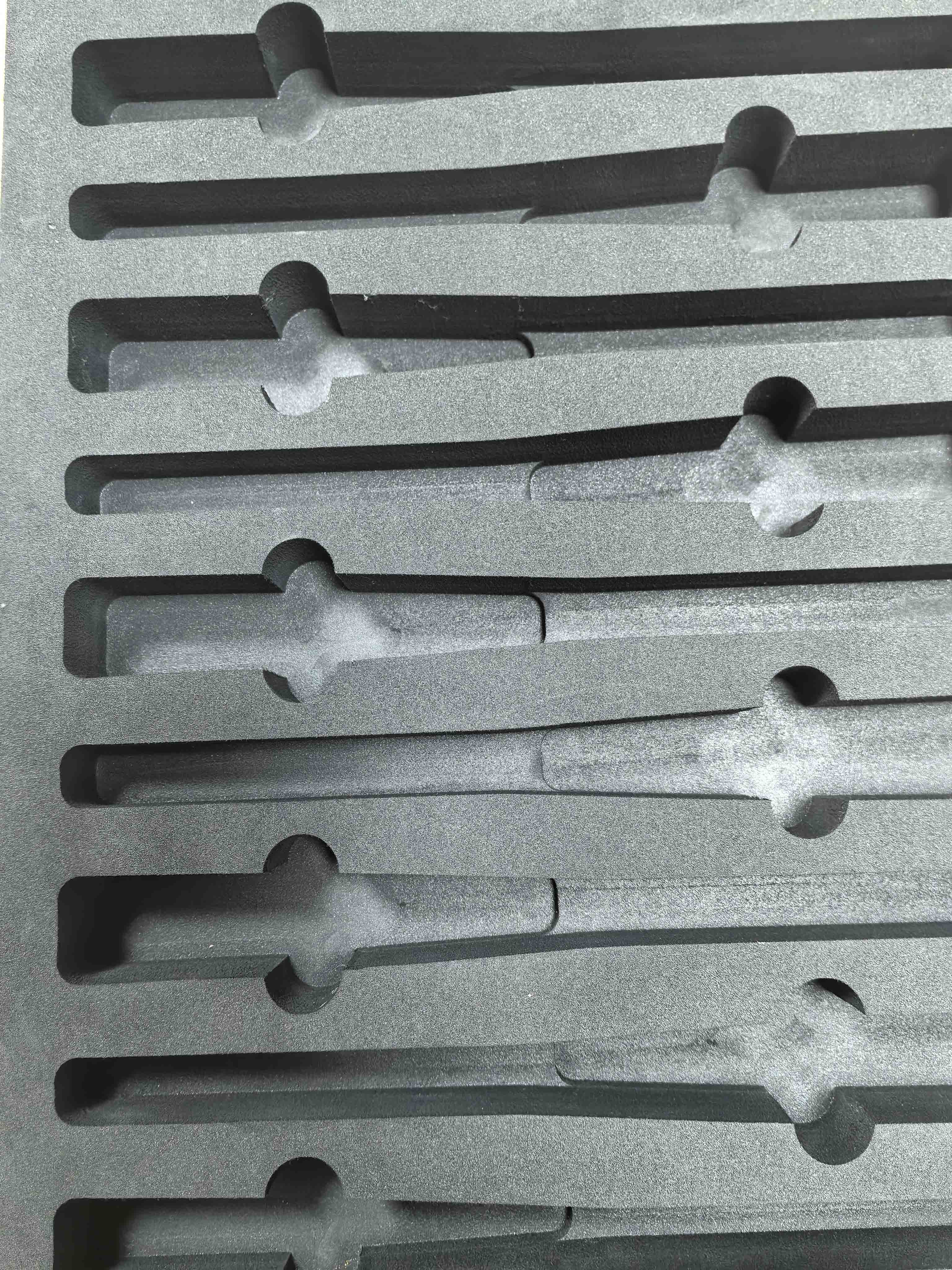

As the market demand for high-precision, high-quality products continues to rise, EVA foam, as an important polymer material, has been widely applied in various industries such as automotive, packaging, footwear, and sporting goods. To better meet market demands, Fubo Company has further improved the manufacturing precision and product quality of EVA foam through a full-chain R&D model, redefining the industry standards.

Precise Manufacturing Process

With its advanced production equipment and technology, Fubo Company has achieved a high-precision manufacturing level of ±0.1mm. In the production process of EVA foam, every detail is meticulously controlled, from raw material selection to the processing of the finished product. Each step ensures the consistency and precision of product dimensions. This high-precision manufacturing process greatly enhances the adaptability and stability of the foam products, significantly strengthening their competitiveness in the high-end market.

Strict Quality Control

Fubo Company always prioritizes quality, keeping the product defect rate within 0.3%, far below the industry standard. By implementing a comprehensive quality inspection system and intelligent monitoring technology, Fubo Company is able to track every step of the production process in real-time, ensuring that each batch of products meets strict quality requirements. In addition, regular equipment maintenance and technological upgrades ensure that the production process remains efficient and stable.

Full-Chain R&D Model

Unlike traditional single-production models, Fubo Company adopts a full-chain R&D model, with every step—from raw material development and production process innovation to testing and validation of final products—being managed internally by the company’s own teams. This integrated R&D model not only keeps the company at the forefront of technological innovation but also effectively reduces production costs and improves manufacturing efficiency.