EVA foams: the first choice for superior performance and customized solutions

2025-02-22

As a manufacturer focusing on the production and R&D of EVA foam, we are well aware of the importance of EVA foam in modern industry and life. With its unique properties and wide range of applications, EVA foam has become the material of choice for many industries. This article will give you a detailed introduction to the characteristics of EVA foam and show the unique advantages of our company in products and services to help you make an informed choice.

![]()

First, the six core characteristics of EVA foam

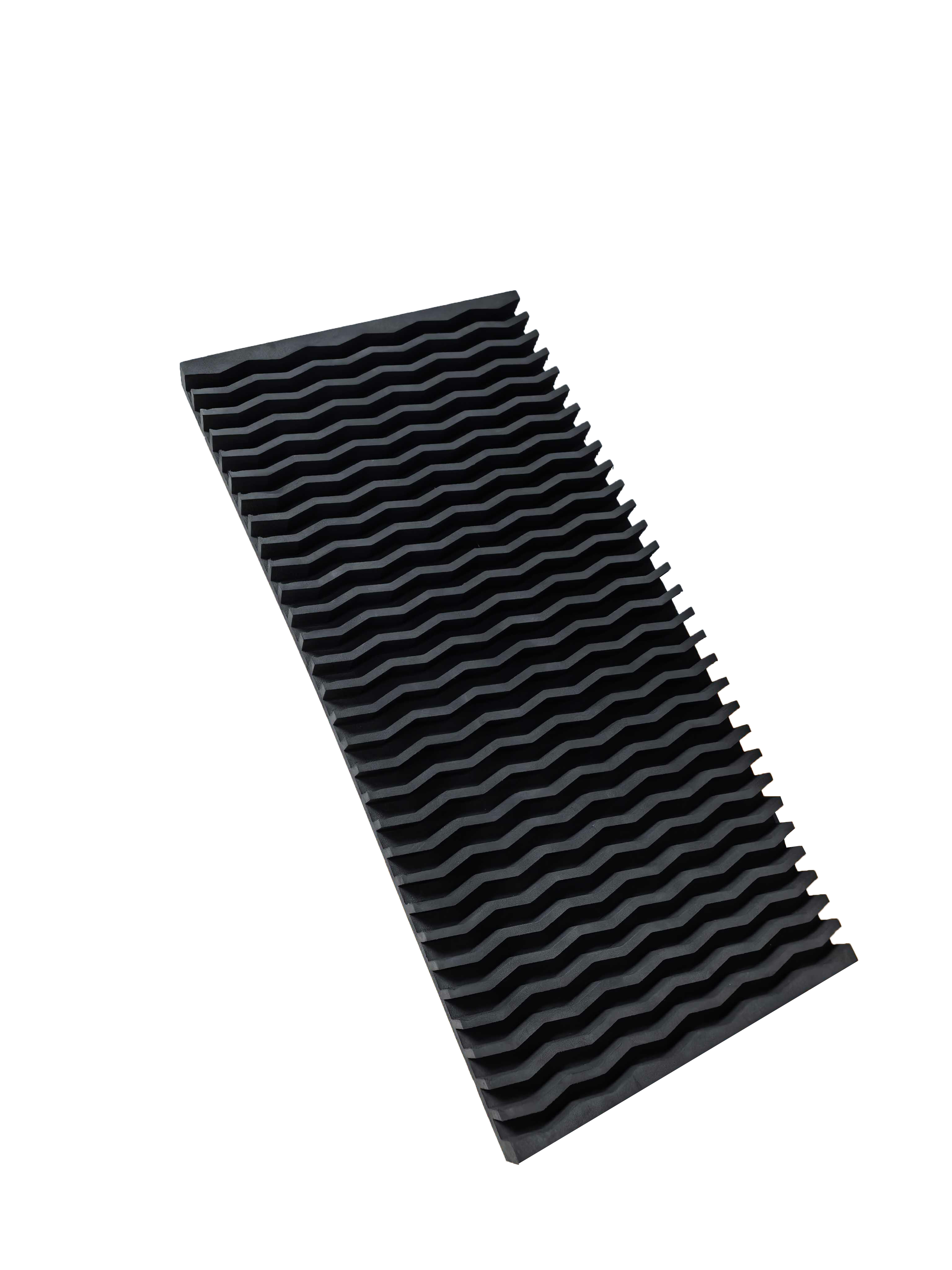

Excellent shock resistance and cushioning performance

EVA foam has high resilience and tension resistance, which can effectively absorb impact forces and protect items from shock and collision damage. Whether it's delicate electronics or fragile crafts, EVA foam provides reliable protection.

Excellent waterproof and moisture-resistant properties

Its closed cell structure makes it non-absorbent and moisture-resistant, and can maintain stable performance even in humid environments, making it suitable for fields that require long-term moisture protection.

Strong corrosion resistance and environmental protection

EVA foam is resistant to corrosion by chemicals such as seawater, grease, acids, alkalis, etc., and at the same time is non-toxic, tasteless, and meets environmental protection requirements, making it an ideal choice for export products and high-end applications.

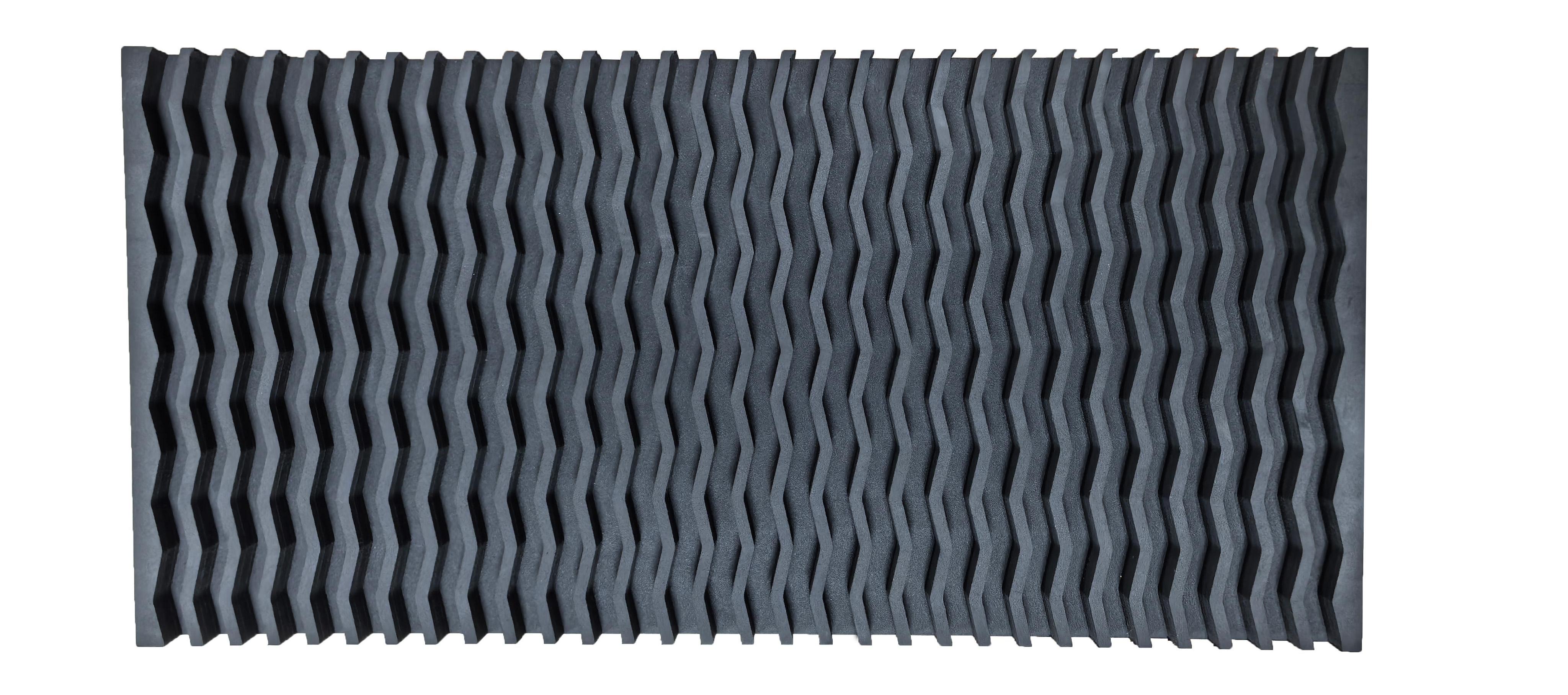

Excellent thermal and acoustic insulation

Its excellent thermal insulation performance, can withstand severe cold and high temperatures, and at the same time, the closed cell structure provides good sound insulation, suitable for construction, automotive and other fields.

Easy to process and customize

EVA foam can be easily processed through hot pressing, cutting, gluing, laminating and other processes to meet the needs of different shapes and sizes, providing customers with highly customized solutions.

Wide range of applications

From shock-resistant packaging for electronics to automotive interiors, from medical equipment to sports equipment, EVA foams are used almost everywhere, demonstrating their versatility and adaptability.

Second, the core advantages of our company

Advanced production technology and equipment

We use international leading production equipment and technology to ensure that each piece of EVA foam has excellent performance and stable quality.

Strict quality control system

From the procurement of raw materials to the delivery of finished products, we implement quality control throughout the process to ensure that products meet international environmental standards and customer requirements.

Rich product line and customized service

We offer EVA foams in a variety of densities, hardnesses, and colors to support customers to customize sizes and shapes according to their needs to meet diverse application scenarios.

Rapid response and efficient delivery

We have a complete supply chain management and logistics system, which can quickly respond to customer needs and ensure timely delivery of products.

Professional after-sales service team

Our technical team is ready to provide customers with product consultation, technical support and solutions to ensure that customers have no worries.