Let every product have "breathing protective armor." ...

2025-02-18

When "vulnerable" meets "resilient"

Today, when the logistics loss rate is as high as 12%, a precision instrument may be scrapped due to transportation vibration, a pair of limited sneakers may be deformed and unsalable due to extrusion, and a high-end medical device may fail due to moisture erosion...... How can you achieve a higher level of protection at a lower cost?

The answer lies in this "breathing" material - EVA foam.

As a manufacturer that has been deeply engaged in the field of polymer materials for XX years, we provide "invisible armor" for XX industries around the world with scientific-grade protection solutions, so that the whole process of products from delivery to delivery is "zero damage".

1. Why choose EVA foam?

3 major genes to solve the industry's protection dilemma:

【Lightweight Innovator】

With a density of only 0.03-0.15 g/cm³, it is 30% lighter than conventional foams, but can withstand a pressure of 50 kg/cm². Just like "slimming" for packaging, the freight has dropped but the protection has not been reduced.

Measured case: After a cross-border e-commerce switched to EVA custom lining, the weight of a single box was reduced by 1.2kg, and the annual logistics cost was saved by more than 800,000 yuan.

【Master of Energy Absorption】

Closed-cell structure + high resilience (≥90%), which instantly converts impact force into deformation energy. Just like a car airbag, it actively "unloads" rather than hitting hard.

Laboratory data: The 1cm thick EVA layer can absorb 85% of the impact of falling, and the anti-drop performance of the mobile phone screen is increased by 3 times.

【Environmental Adaptation Expert】

-40°C extremely cold and not brittle, 80°C high temperature without deformation, IPX7 waterproof and moisture-proof, even resistant to medical disinfectant corrosion.

Scenario verification: After an auto parts factory in northern China adopted EVA gaskets, the complaint rate of low-temperature oil leakage decreased by 67%.

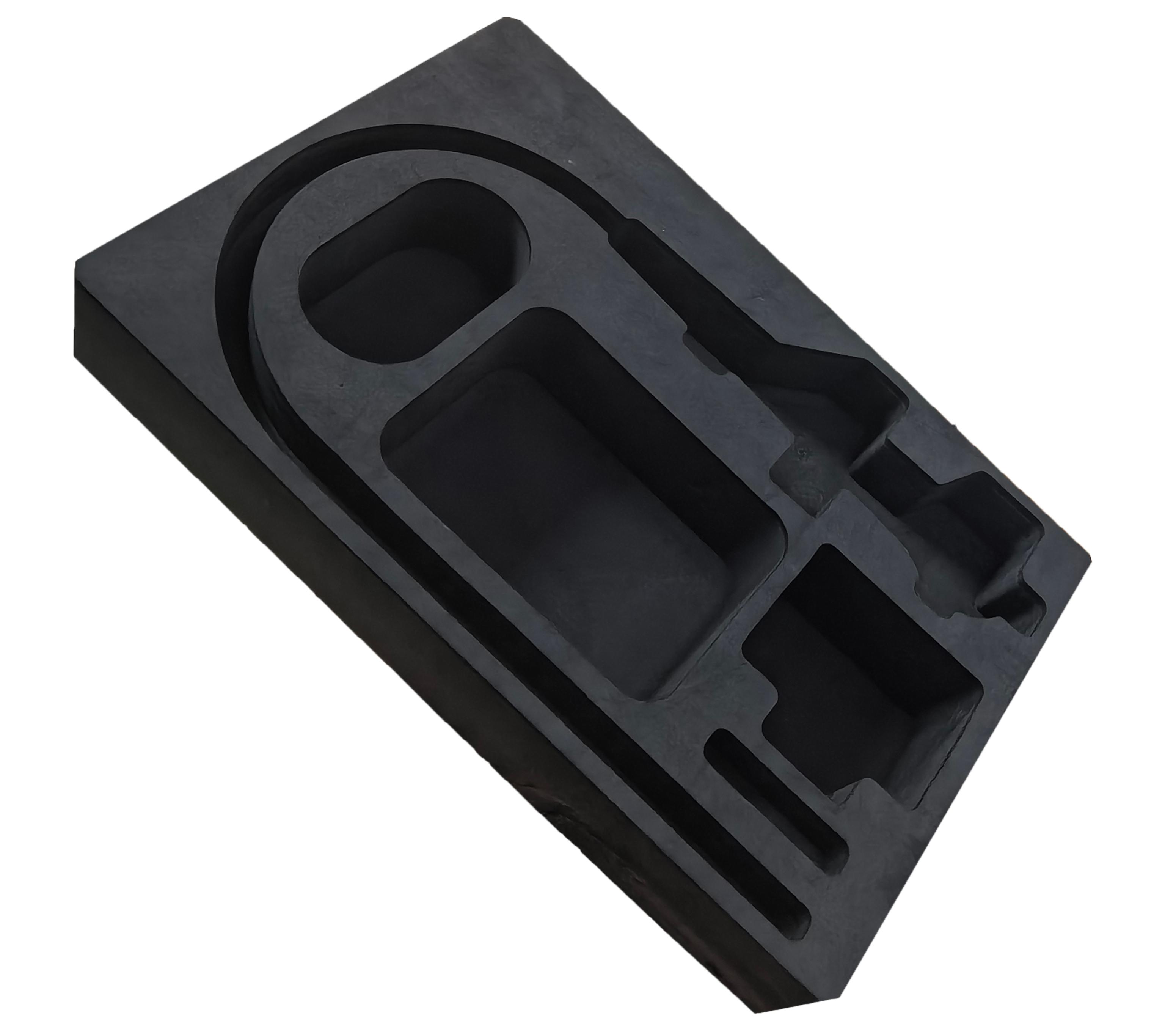

![]() 2. How can EVA foam "accurately reduce losses" for different industries?

2. How can EVA foam "accurately reduce losses" for different industries?

1. Electronics industry: put on a "shock suit" for precision components

Pain points: Transportation bumps lead to false soldering of circuit boards and leakage of screens

Solution: 2mm ultra-thin EVA gasket + honeycomb structure design, cushioning performance increased by 40%

Customer testimonial: "After switching to EVA inner pallets, our return rate for our action cameras dropped from 5% to 0.3%" – a smart hardware brand

2. Medical Industry: "Gentle Armor" in a Sterile Environment

Pain points: Traditional foam chips contaminate surgical instruments

Solution: Medical-grade EVA raw material + dust-free workshop die-cutting, ISO 10993 biocompatibility certification

Scenario: The endoscope transport case uses EVA custom card slots, and the sterilization cycle is shortened by 2 hours

3. New energy field: the "invisible guard" of battery safety

Pain point: Lithium battery collision causes thermal runaway

Solution: Flame retardant EVA foam (UL94 V-0 grade) + double-sided conductive adhesive to achieve double protection of seismic & electromagnetic shielding