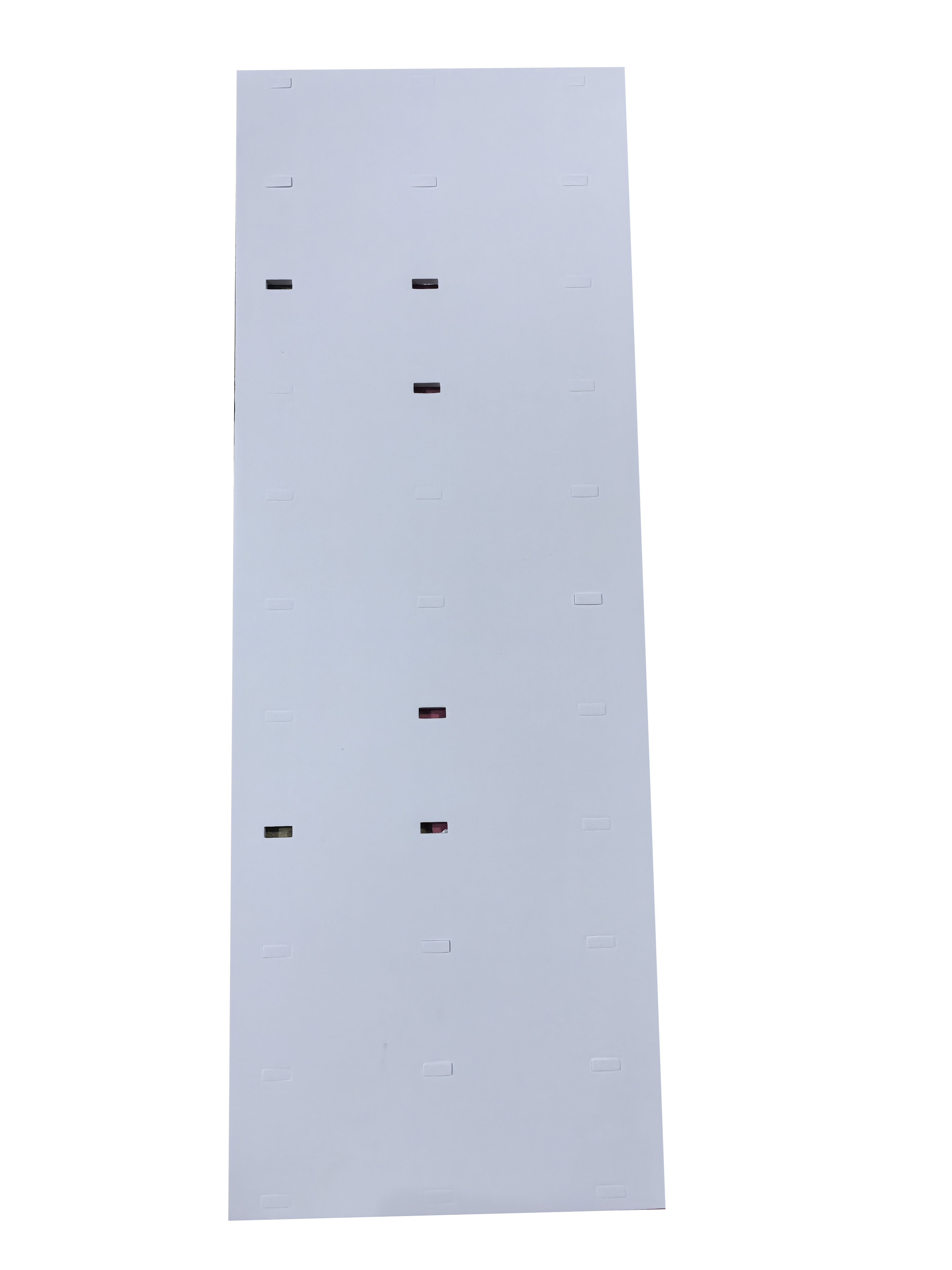

Professional custom high density die-cut Eva foam foam for box packaging to protect foam insertion

2025-02-10

As an EVA foam manufacturer, I just received a call asking about the comparison between EVA and PE materials, and which one is better. In fact, compared to PE materials, EVA material has improved environmental stress cracking resistance, and its capacity to absorb fillers has increased. This allows for the use of more reinforcing fillers to avoid or reduce the decline of EVA’s mechanical properties. Below, let me, as a flame-retardant EVA foam manufacturer, explain the performance differences between EVA and PE materials.

When the ethylene vinyl acetate (EVA) content in EVA materials is less than 20%, it can be used as plastic. EVA has excellent low-temperature performance, and its thermal decomposition temperature is relatively low, around 230°C. As the molecular weight increases, the softening point of EVA rises, but its processability and surface gloss decrease, while its strength, impact toughness, and environmental stress cracking resistance improve. EVA's chemical resistance and oil resistance are slightly inferior to those of PE and PVC, and these properties change significantly as the vinyl acetate content increases.

The performance improvement of EVA foam materials compared to PE is mainly in elasticity, flexibility, gloss, and permeability. In addition, its environmental stress cracking resistance has improved, and its ability to absorb fillers has increased. This allows for the incorporation of more reinforcing fillers to avoid or reduce the decline of EVA's mechanical properties. EVA can also be modified for new applications, with two main methods: first, using EVA as the backbone to graft other monomers; second, partially hydrolyzing EVA.

EVA foam material is an ethylene-vinyl acetate copolymer, with the vinyl acetate (VA) content generally between 5% and 40%. Compared to polyethylene, EVA introduces vinyl acetate monomers into the molecular chain, reducing the crystallinity and improving flexibility, impact resistance, filler compatibility, and heat-sealability. It is widely used in fields such as foam shoe materials, functional greenhouse films, packaging films, hot melt adhesives, wires and cables, and toys.

Dongguan Fubo Packaging Products Co., Ltd. mainly produces and processes various colors of anti-static EVA foam, conductive EVA foam, flame-retardant EVA foam, fireproof EVA sponge, tool box linings, and more. The company offers high-quality products at competitive prices and looks forward to cooperating and achieving mutual success.