In today’s competitive market, businesses across industries are prioritizing innovative packaging solutions that combine durability, functionality, and aesthetic appeal. Manufacturer-customized high-quality EVA (ethylene-vinyl acetate) bags with foam-lined inner tray packaging have emerged as a game-changer for brands seeking to protect their products while enhancing their unboxing experience. This article explores the features, benefits, and applications of these versatile packaging solutions.

What Makes EVA Bags Stand Out?

EVA is a lightweight, flexible, and highly durable polymer known for its shock-absorbing properties, water resistance, and resilience to extreme temperatures. Unlike traditional plastics, EVA is non-toxic, odorless, and recyclable, aligning with modern sustainability goals. When crafted into customized bags, EVA offers:

Superior Protection: Guards against impacts, moisture, and abrasion during transit.

Custom Fit: Tailored dimensions and shapes to snugly fit products, minimizing movement.

Reusable Design: Durable enough for repeated use, ideal for premium or high-end goods.

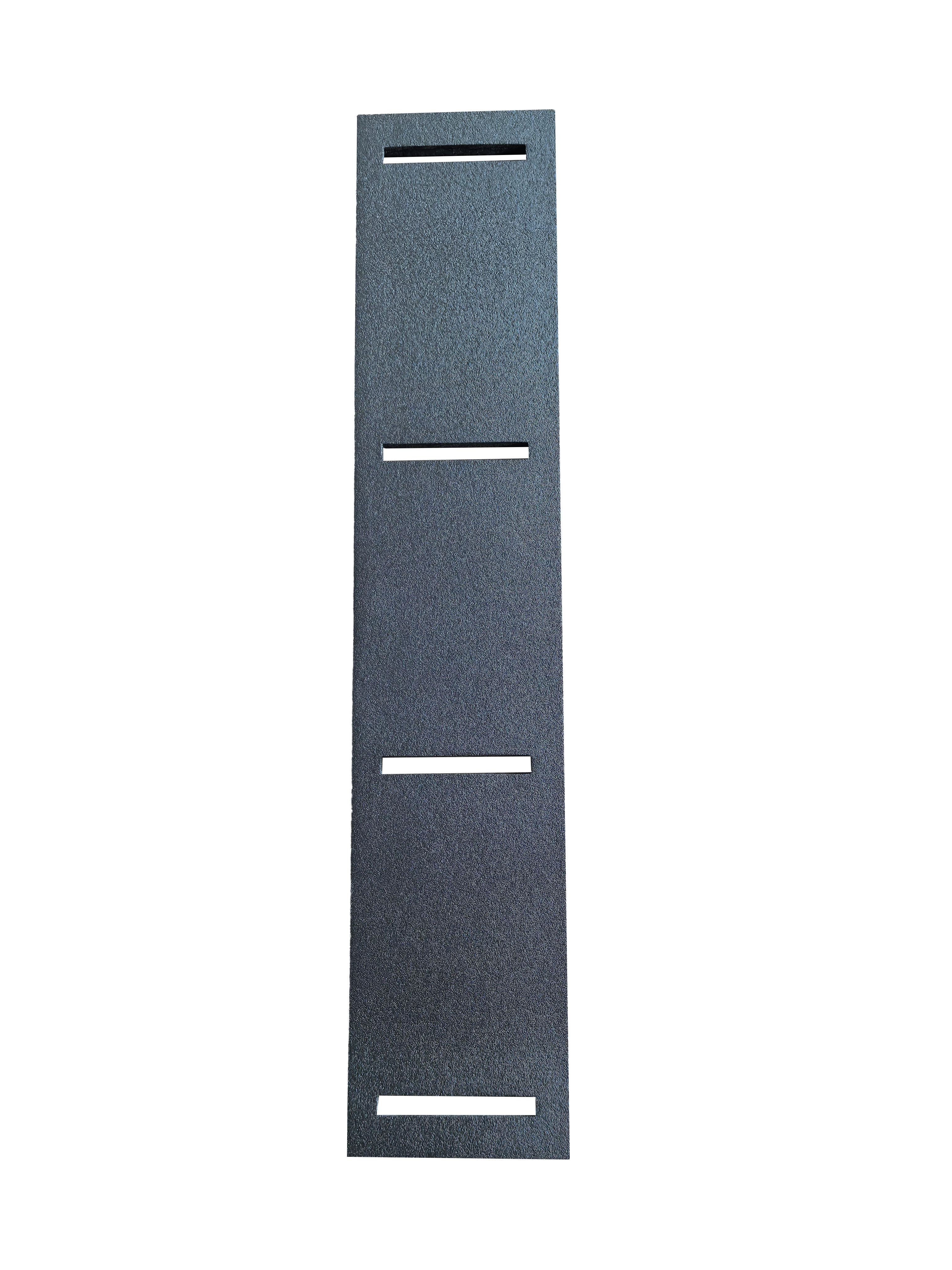

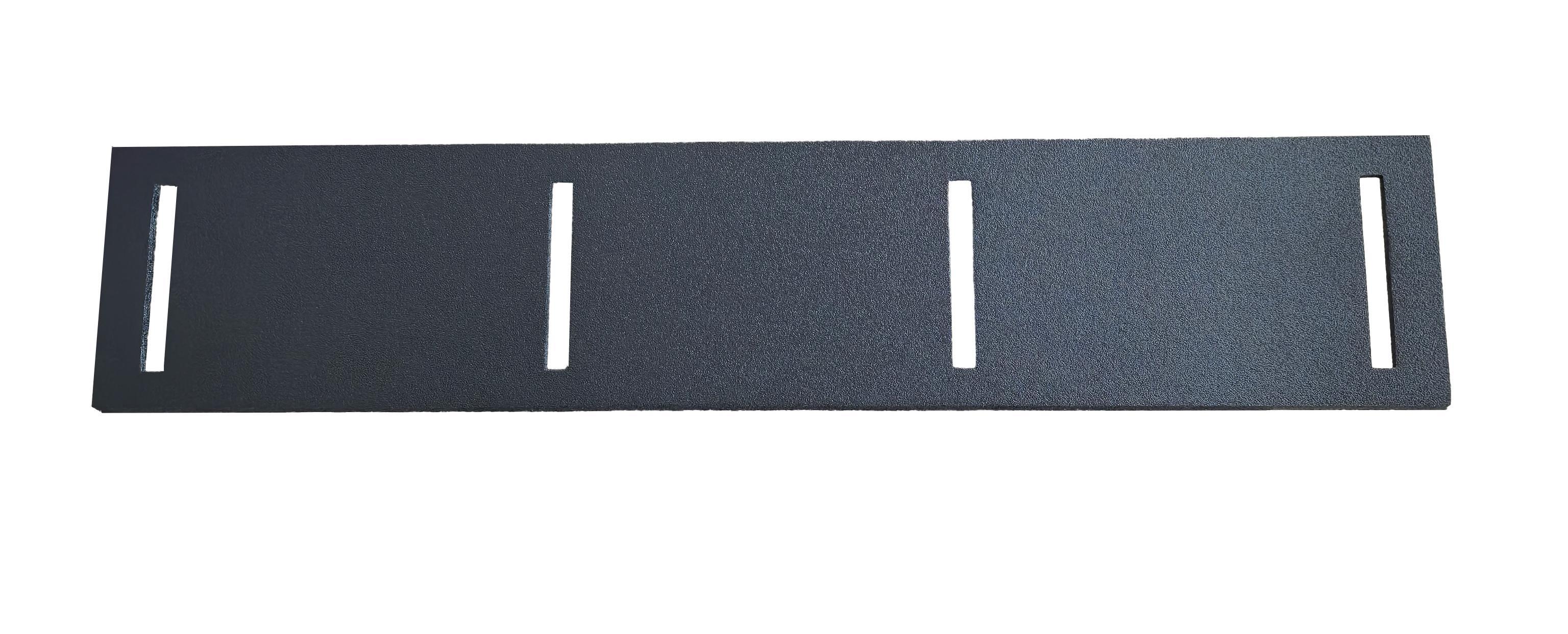

The Role of Foam-Lined Inner Trays

The integration of foam-lined inner trays elevates EVA bags from simple carriers to precision packaging systems. These trays are typically made from high-density foam (e.g., polyethylene or polyurethane) and serve multiple purposes:

Cushioning: Absorbs shocks and vibrations, protecting fragile items like electronics, medical devices, or luxury accessories.

Compartmentalization: Custom-cut compartments securely hold multiple components (e.g., gadgets, tools, or cosmetics) in place.

Professional Presentation: Adds a polished, organized look to the packaging, reinforcing brand credibility.

Customization: Tailored to Your Brand’s Needs

One of the standout features of manufacturer-customized EVA bags is their adaptability. Businesses can collaborate with manufacturers to design packaging that aligns with their unique requirements:

Size and Shape: Optimized for products of any dimensions, from small jewelry to industrial equipment.

Color and Finish: Choose from matte, glossy, or textured surfaces, with brand-specific Pantone color matching.

Branding Opportunities: Add logos, slogans, or QR codes via embossing, debossing, silk-screen printing, or laser engraving.

Additional Features: Include zippers, handles, dividers, or anti-static linings for specialized applications.

Applications Across Industries

EVA bags with foam-lined trays are versatile enough to serve diverse sectors:

Electronics: Safeguard smartphones, drones, or circuit boards from static and physical damage.

Medical Equipment: Ensure sterile, shockproof storage for sensitive instruments.

Automotive: Organize tools, spare parts, or diagnostic devices in workshops or for transport.

Luxury Goods: Elevate the unboxing experience for watches, eyewear, or designer accessories.

Outdoor Gear: Protect camping equipment, cameras, or diving gear from harsh environments.

Why Choose a Professional Manufacturer?

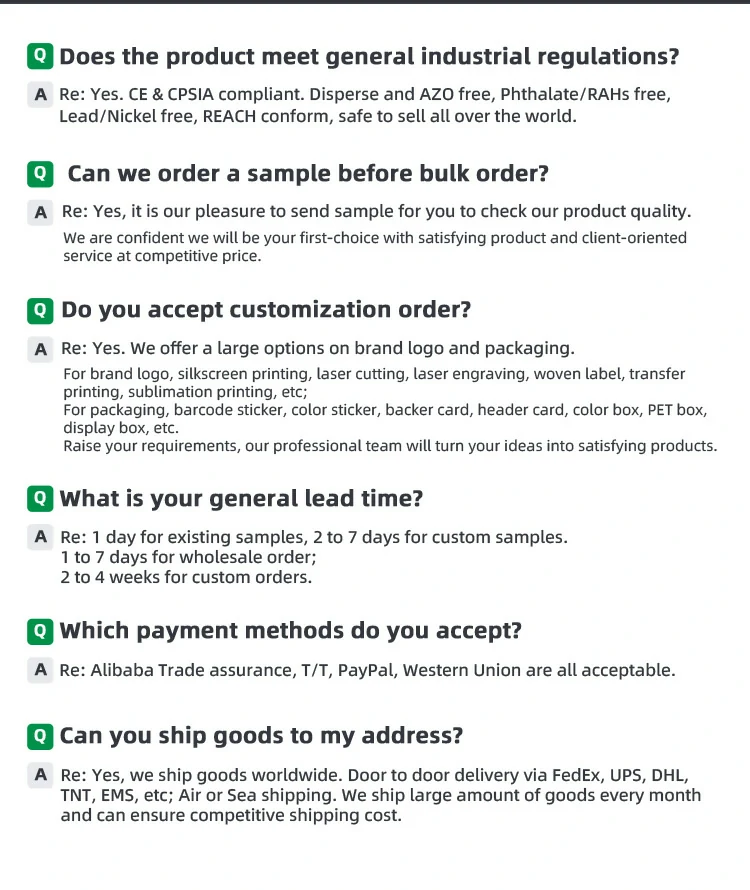

Partnering with an experienced manufacturer ensures:

Quality Assurance: Rigorous testing for tear resistance, load capacity, and environmental durability.

Cost Efficiency: Bulk production reduces per-unit costs without compromising quality.

Sustainability Options: Access to eco-friendly EVA blends or biodegradable foam alternatives.

End-to-End Support: From prototyping to final delivery, streamline your packaging supply chain.