In today’s competitive market, product protection and presentation are critical to ensuring customer satisfaction and brand reputation. For industries ranging from electronics and medical devices to automotive parts and luxury goods, EVA foam lined inner tray packaging has emerged as a go-to solution for safeguarding delicate items during storage and transit. Customized manufacturing of these trays ensures they meet precise requirements, offering tailored protection and enhancing unboxing experiences. Let’s explore why partnering with a specialized EVA foam lined inner tray packaging manufacturer is a strategic choice for businesses.

Why EVA Foam Lined Inner Tray Packaging?

Ethylene-Vinyl Acetate (EVA) foam is a versatile, durable, and lightweight material known for its exceptional cushioning properties. When used in inner tray packaging, it offers:

Shock Absorption: Protects fragile items from impacts, vibrations, and drops.

Custom Fit: Contoured designs hold products securely in place, minimizing movement.

Moisture Resistance: Ideal for humid environments or products sensitive to water damage.

Lightweight Structure: Reduces shipping costs compared to heavier alternatives like wood or metal.

Aesthetic Flexibility: Available in multiple colors, textures, and finishes to align with brand aesthetics.

The Power of Customization

Generic packaging solutions often fail to address unique product dimensions, shapes, or industry-specific requirements. A customized EVA foam inner tray manufacturer bridges this gap by offering:

Precision Engineering: Laser cutting and CNC machining ensure exact fits for complex geometries.

Multi-Layer Designs: Incorporate compartments for accessories, cables, or documentation.

Branding Integration: Add logos, embossing, or QR codes for a premium unboxing experience.

Material Optimization: Adjust foam density (e.g., soft, medium, firm) based on product weight and fragility.

Industries That Benefit from Custom EVA Foam Trays

Electronics: Protect sensitive components like circuit boards, smartphones, or drones.

Medical Devices: Ensure sterility and safety for surgical tools, diagnostic equipment, and implants.

Automotive: Safeguard precision parts like sensors, connectors, or LED lights.

Luxury Goods: Elevate presentation for watches, jewelry, or high-end cosmetics.

Aerospace: Meet stringent standards for delicate aviation components.

Choosing the Right EVA Foam Lined Inner Tray Manufacturer

When selecting a manufacturing partner, prioritize companies that offer:

End-to-End Services: From design consultation and prototyping to mass production.

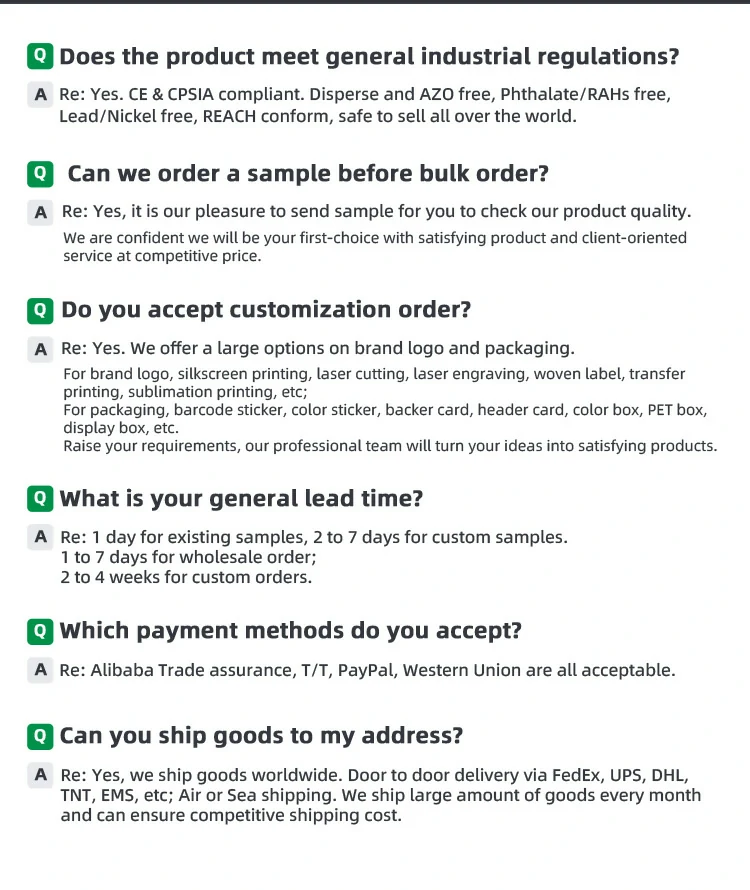

Material Expertise: High-quality EVA foam with certifications (e.g., RoHS, REACH).

Advanced Technology: State-of-the-art machinery for precision and scalability.

Sustainability: Eco-friendly foam options and waste-reduction practices.

Global Logistics: Timely delivery and support for international clients.

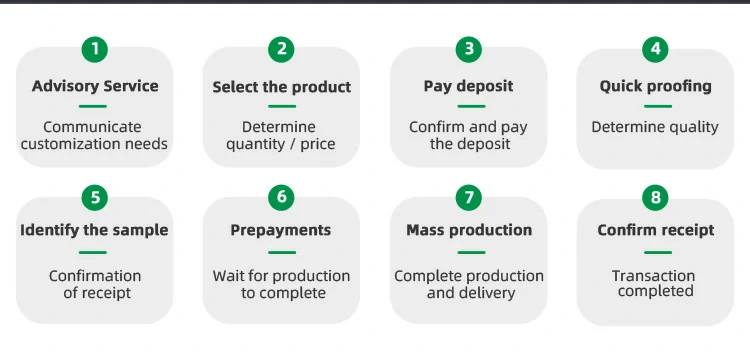

The Customization Process: From Concept to Delivery

Requirement Analysis: Collaborate with engineers to define product dimensions, protection needs, and branding goals.

3D Design & Prototyping: Create digital models and physical samples for testing.

Material Selection: Choose foam thickness, color, and additional features (e.g., anti-static layers).

Production: High-precision cutting and assembly using automated systems.

Quality Assurance: Rigorous testing for durability, fit, and functionality.

Why Invest in Custom EVA Foam Trays?

Reduce Damage Claims: Minimize losses from transit-related breakages.

Enhance Brand Perception: Professional packaging reflects quality and attention to detail.

Streamline Operations: Optimize storage and assembly with tailored designs.

Sustainability: Reusable and recyclable trays align with eco-conscious initiatives.

Conclusion

Partnering with an experienced EVA foam lined inner tray packaging customized manufacturer ensures your products are protected, presented impeccably, and aligned with your brand’s values. Whether you’re launching a new product or upgrading existing packaging, customized EVA foam solutions deliver unmatched performance and customer satisfaction.

Ready to Elevate Your Packaging?

Contact a trusted manufacturer today to discuss your project and unlock the benefits of precision-engineered EVA foam trays tailored to your needs.