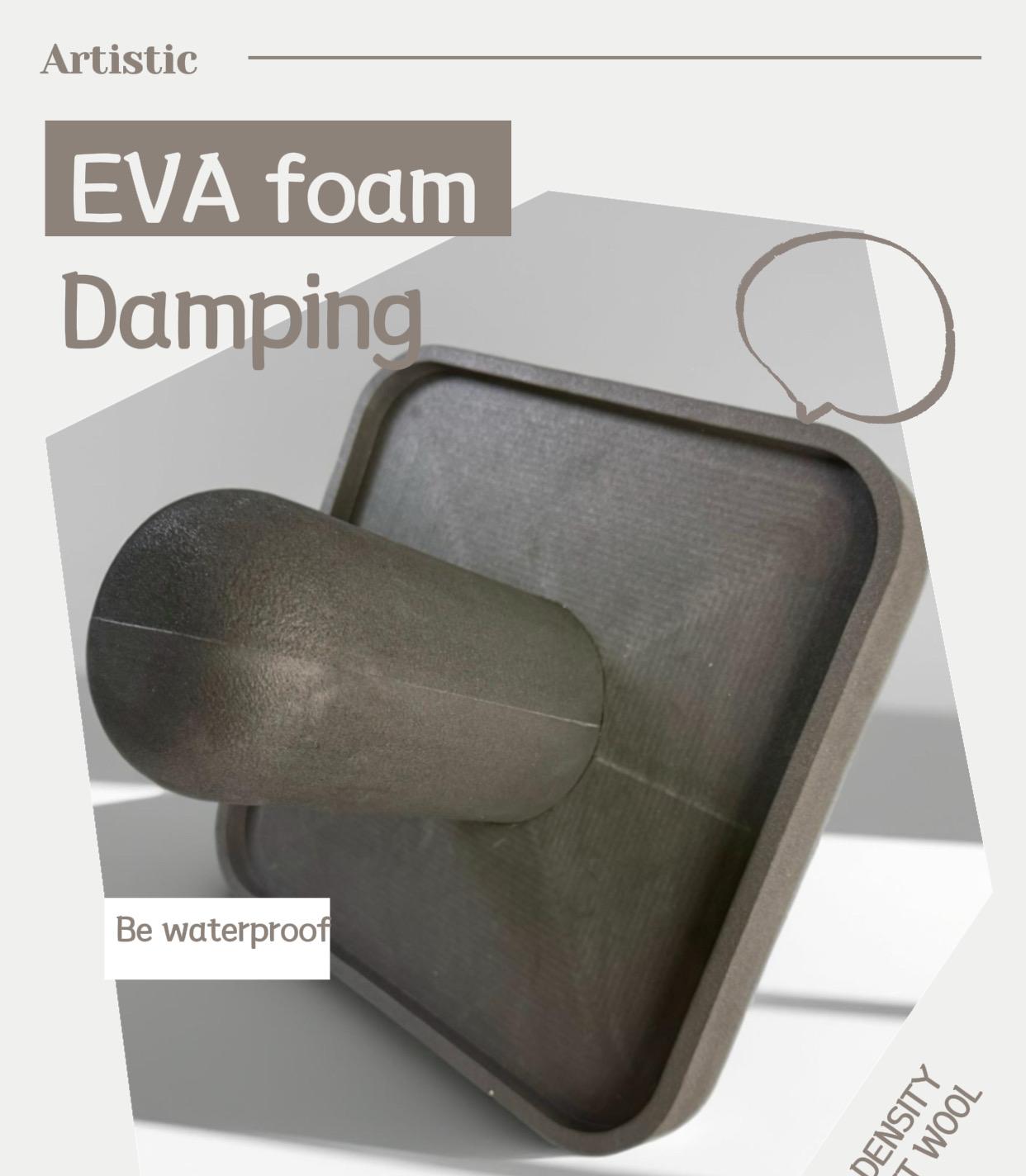

Are you seeking a perfectly tailored solution for your shock and vibration damping needs? We specialize in crafting high-quality, custom shock absorption products made from EVA foam, designed to meet the most demanding specifications. Our featured product, as seen in the image, exemplifies our commitment to precision engineering. This particular piece was developed through a sophisticated combination of CNC carving and advanced lamination techniques.

The use of EVA foam as our primary material offers excellent cushioning, resilience, and lightweight properties, making it ideal for effective shock and vibration absorption. The CNC carving process allows for unparalleled accuracy, ensuring that every curve and dimension of the EVA foam is meticulously replicated from your design. This precision cutting is crucial for optimal performance and a perfect fit in any application. Following the carving, multiple layers of EVA foam are expertly laminated together, enhancing the product's durability, resilience, and overall damping capabilities. This meticulous lamination process creates a robust and highly effective buffer against impacts and vibrations.

We understand that off-the-shelf solutions often fall short, which is why we focus on custom manufacturing. Whether you require unique shapes, specific densities of EVA foam, or specialized damping characteristics, our team is equipped to deliver. Our dedication to high-quality EVA foam materials and manufacturing processes ensures that each product provides superior performance and longevity. Experience the difference that custom-engineered, high-quality EVA foam shock absorption can make for your equipment and operations. Partner with us for bespoke solutions crafted with precision cutting and expert lamination.