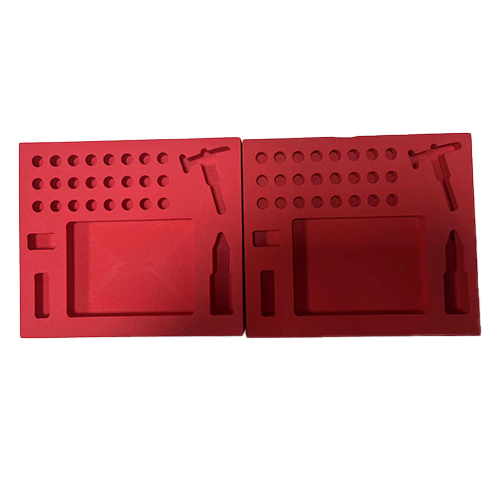

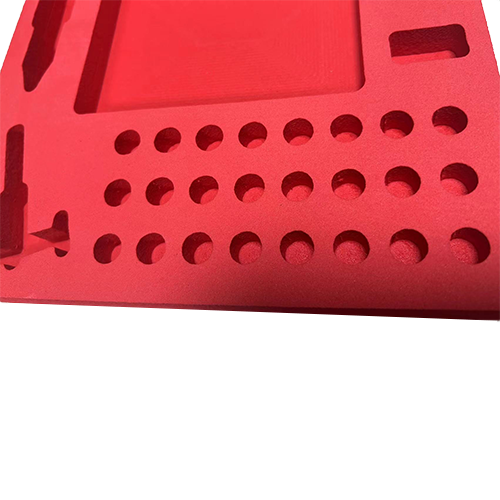

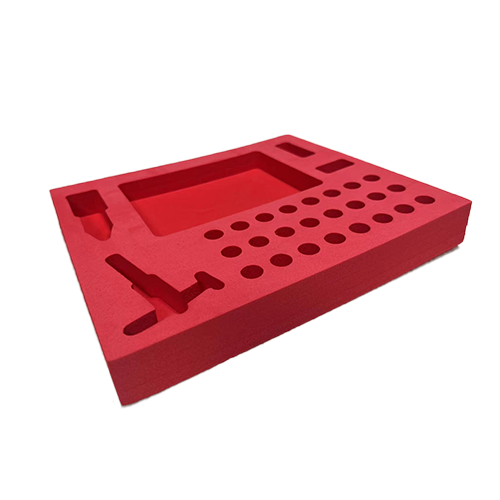

First of all, let's look at the principle of engraving EVA FOAM, how to make it. The engraving eva packaging lining is made of CNC computer engraving machine, which has many advantages compared with the traditional knife mold adhesive process. First of all to carve, the first is the need for engraving machine, from the engraving machine point of view, the domestic better manufacturers have fine carving, Shicheng, Haida and other manufacturers. In terms of function, the engraving machine has 4 axes, 6 axes, 8 axes or more, the more the number of axes, the more expensive the price. Of course, the speed and efficiency of carving EVA is faster.

Secondly set the program, in fact, many colleagues who do EVA say that engraving machine, need programming, it is difficult to learn, in fact, if you have some basic knowledge, understand the working principle of engraving machine, it is not difficult to learn. Engraving machine is designed and drawn by the computer's special engraving software, and the computer automatically transmits the design and layout information to the engraving machine controller, and then the controller converts the information into a power signal (pulse train) that can drive the stepper motor or servo motor, and controls the engraving machine host to generate X, Y, Z three-axis engraving cutting subgrade. The three axes are controlled by a computer program, so the whole EVA material is not integrated into the product, no adhesive traces, with 3D effect. In addition, the production process does not require molds, and the replacement of contents does not bear additional costs, which can support a small number of diversified orders