Why Is EVA Foam So Expensive? Understanding the Cost Behind High-Performance Foam

2025-07-24

Table of Contents Why Is EVA Foam So Expensive

- Introduction

- What Is EVA Foam?

- Key Factors That Increase EVA Foam Cost

- High-Quality Manufacturing Standards

- Customization and Specialization

- Advanced Industrial Applications

- Supply Chain & Material Costs

- Why Choose Professional Manufacturers Like Fubo?

- Summary Table

- Reference Links

Introduction Why Is EVA Foam So Expensive

EVA (Ethylene-Vinyl Acetate) foam is widely used across industries due to its versatility, durability, and exceptional cushioning performance. However, many businesses and consumers often ask: Why is EVA foam so expensive? The answer lies in a combination of production technology, material quality, customization requirements, and specialized applications. In this article, we’ll explore the primary reasons behind the premium price of EVA foam and how trusted manufacturers like Fubo deliver value beyond cost.

What Is EVA Foam?

EVA foam is a closed-cell, flexible polymer foam made from ethylene and vinyl acetate. It is known for its excellent shock absorption, durability, and waterproof properties. It is used in everything from yoga mats and toys to electronics packaging and aerospace components.

Common Applications:

- Footwear and sports equipment

- Protective packaging for electronics and appliances

- Drone insulation and shock absorption

- Foam toys and educational tools

- Soilless farming solutions

Key Factors That Increase EVA Foam Cost

Let’s explore the core elements that make high-performance EVA foam more expensive compared to other materials.

1. Raw Material Purity and Composition

- Higher vinyl acetate content increases elasticity and resilience — but also the price.

- Purified resins offer better performance in shock absorption and longevity.

- Color-stable and UV-resistant additives add to the cost.

2. Advanced Processing Technology

- Precision molding and foaming control for tight tolerances.

- Multiple stages of heat and pressure treatments.

- Specialized machinery for die-cutting and lamination.

3. Environmental Compliance

- Eco-friendly, non-toxic, and recyclable EVA foam requires stricter manufacturing controls.

- Compliance with international standards (e.g., REACH, RoHS, SGS) raises production costs.

High-Quality Manufacturing Standards

Professional manufacturers like Fubo, located in Xiegang, Dongguan, produce EVA foam under strict industrial standards, offering enhanced physical and chemical properties for demanding sectors.

Fubo’s Quality Assurance Includes:

- Uniform cell structure and density control

- Durable and lightweight products

- Efficient production for large-scale orders with customization

Common Fubo EVA Foam Products:

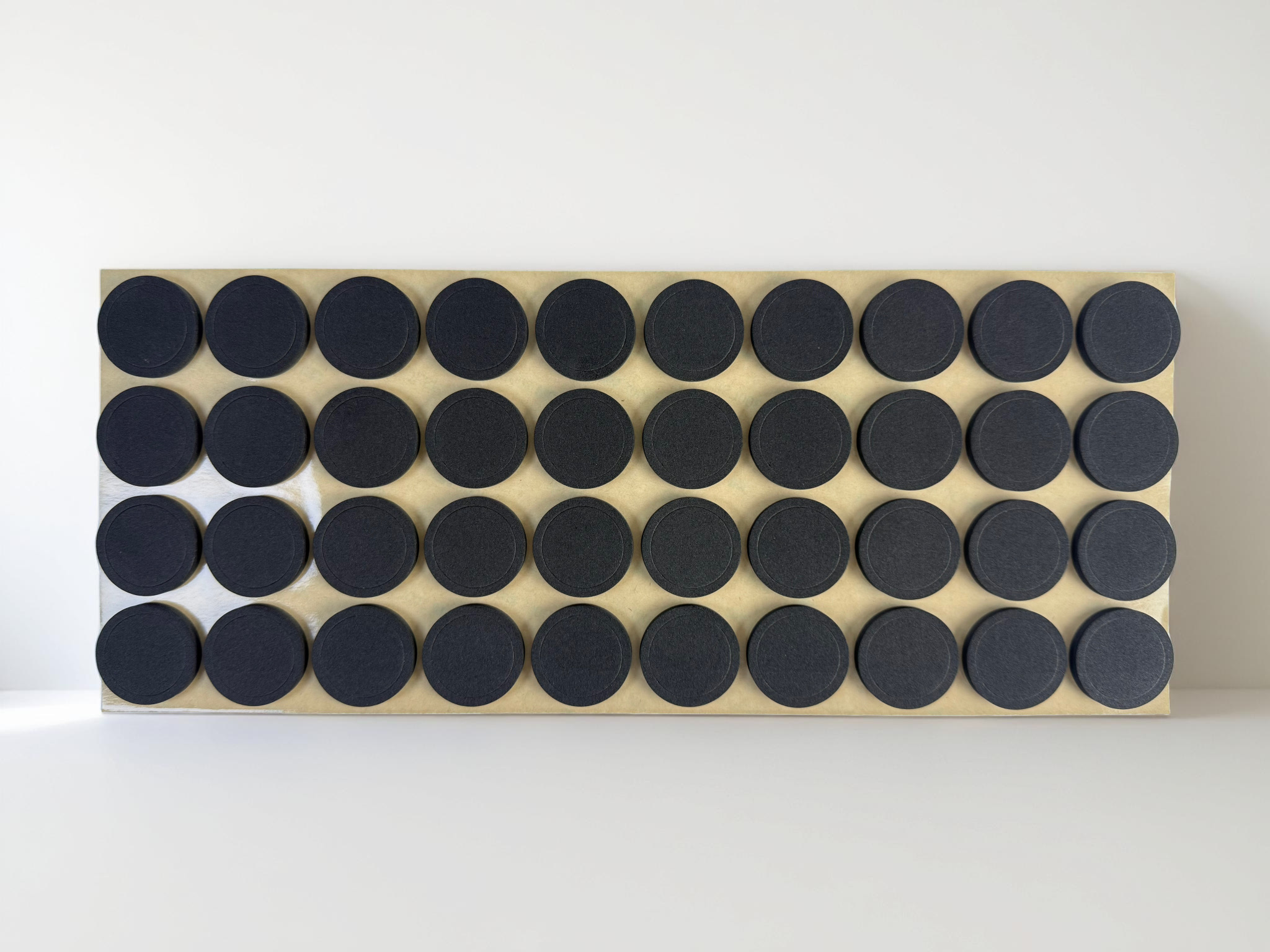

- Customized EVA foam inner lining

- EVA foam swimming boards

- EVA toys with numerical letters

- EVA cushioning and protective material

- Soilless culture foam boards

Customization and Specialization

Customized EVA foam solutions require mold creation, CAD design, and iterative prototyping, especially for high-precision industries like electronics, semiconductors, or aerospace.

Customization Drives Price Through:

- Tooling and mold development fees

- Low-volume specialized production runs

- Client-specific adjustments in density, hardness, or fire retardancy

Advanced Industrial Applications

Many industries rely on engineered EVA foam for protection, insulation, and structural support in extreme environments. These use cases require precise engineering, strict testing, and consistent performance.

Key Application Examples:

- Electronics: Anti-static EVA foam protects circuit boards

- Drones: Shock-absorbing pads for impact resistance

- Medical Devices: EVA used in sterilizable and skin-safe packaging

- Semiconductors: Customized foam for vibration isolation during transport

Supply Chain & Material Costs

The price of EVA foam is also influenced by global raw material prices, logistics costs, and energy consumption. COVID-19 and global disruptions have raised the cost of petrochemical-based polymers like EVA resin.

Other Contributing Factors:

- Shipping and freight rates (especially for large foam sheets)

- Workforce and labor skill in specialized production

- Import/export duties depending on the destination country

Why Choose Professional Manufacturers Like Fubo?

Choosing a professional EVA foam manufacturer ensures you’re paying for quality, consistency, and custom-fit functionality. Fubo not only delivers top-tier EVA solutions but also offers OEM services and industry-grade performance.

Benefits of Partnering with Fubo:

- Experienced R&D team for custom applications

- Factory-direct pricing and flexible order quantities

- High-performance EVA foam for industrial use

Summary Table

| Cost Factor | Impact on EVA Foam Pricing |

|---|---|

| Material Quality | High-grade EVA resins increase elasticity and lifespan |

| Processing Technology | Precision foaming and molding raise production cost |

| Customization | Client-specific requirements increase tooling and labor |

| Industrial Applications | Used in sectors that demand strict tolerances and certification |

| Environmental Compliance | Eco-compliance and safety standards raise operational overhead |

| Logistics & Global Supply Chain | Freight, tariffs, and resin costs contribute to final price |

Reference Links

- Fubo Official Website

- Wikipedia – EVA Foam

- Alibaba – EVA Foam Listings

- REACH Compliance Portal