Introduction and Use of Closed Cell EVA Foam: A Comprehensive Guide

2025-06-25

Table of Contents

- Introduction

- What Is Closed Cell EVA Foam?

- Key Properties and Benefits

- Common Industrial Applications

- Fubo's Closed Cell EVA Foam Products

- Why Choose Closed Cell Over Open Cell Foam?

- Customization and OEM Services

- Environmental and Safety Considerations

- Summary Table

Introduction

Closed cell EVA foam is one of the most versatile materials used across various industries for packaging, insulation, cushioning, sports, and electronics. Known for its shock absorption, water resistance, and flexibility, EVA (Ethylene-Vinyl Acetate) foam plays a critical role in both industrial and consumer products.

Fubo, a professional foam manufacturer based in Dongguan, China, is a leader in providing high-quality closed cell EVA foam solutions to sectors like electronics, sports, hardware, medical devices, and drones. This article introduces closed cell EVA foam, its properties, uses, and how Fubo customizes solutions to meet specific industry needs.

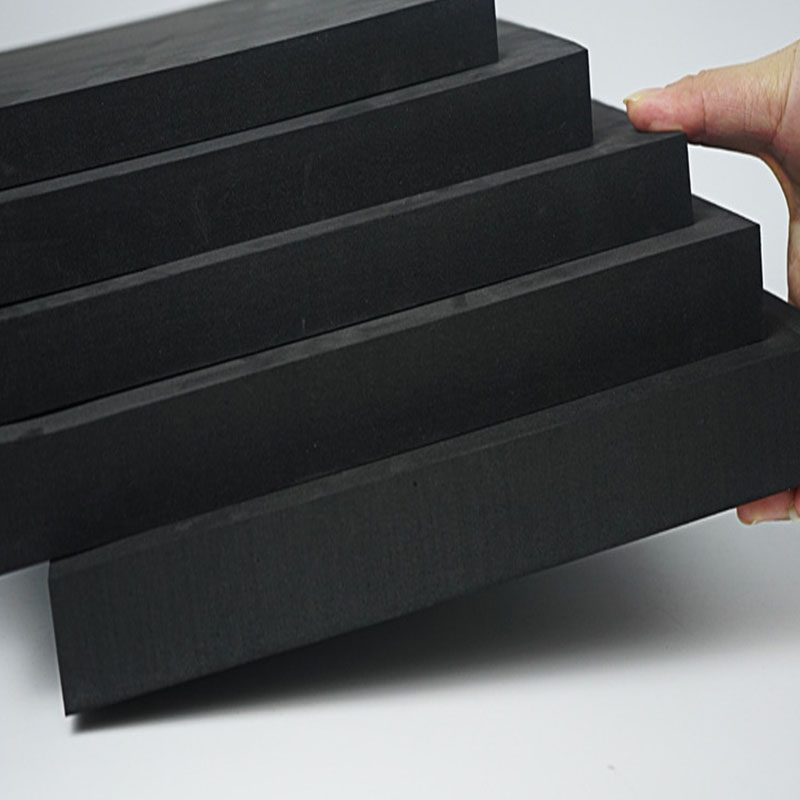

What Is Closed Cell EVA Foam?

Closed cell EVA foam is a type of polymer foam made from ethylene-vinyl acetate that features a tightly packed structure with no air pockets between cells. This structure makes it:

- Water-resistant

- Shock absorbing

- Flexible yet durable

- Insulating against temperature and sound

Unlike open-cell foam, closed-cell EVA is more rigid, making it suitable for impact protection, padding, and high-resilience applications.

Key Properties and Benefits

Closed cell EVA foam offers a range of performance benefits:

- Waterproof and Moisture Resistant: Does not absorb water, ideal for marine and outdoor use

- High Shock Absorption: Used in protective gear and industrial packaging

- Lightweight: Easy to transport and install

- Non-toxic and Safe: Suitable for children’s toys, medical use, and food-grade packaging

- Customizable: Can be molded, cut, or laminated into any shape or thickness

- Good Thermal and Acoustic Insulation

Common Industrial Applications

EVA foam’s diverse characteristics make it popular in various sectors:

1. Electronics & Appliances

- Used for anti-static packaging, shock pads, and insulation layers in devices

- Ideal for precision equipment like semiconductors and circuit boards

2. Sports & Leisure

- Applied in yoga mats, kickboards, life vests, and protective sports gear

- High-density EVA improves stability and comfort

3. Medical and Health Equipment

- Safe, hypoallergenic material for cushioning and support products

4. Drones & Robotics

- Provides impact-resistant housing for drones and aerial vehicles

5. Packaging & Transportation

- Custom-cut foam inserts for delicate hardware or instruments

6. Gardening and Hydroponics

- Used in soilless culture foam boards for plant support and water retention

Fubo's Closed Cell EVA Foam Products

Fubo offers an extensive range of EVA foam-based solutions tailored for diverse sectors. Their products include:

1. Customized EVA Foam Inner Lining

- Precision cut for packaging electronics, medical tools, and fragile goods

- Excellent cushioning and anti-vibration performance

2. EVA Foam Swimming Board

- Lightweight, buoyant, waterproof

- Used in swimming training and aqua therapy

3. EVA Toys with Numerical Letters

- Safe for children: soft, non-toxic, colorful

- Educational use in schools and daycare

4. EVA Cushioning and Protective Material

- Available in sheets, rolls, or custom-cut shapes

- Ideal for helmets, sports pads, and medical braces

5. Soilless Culture Foam Board

- Used in hydroponic farming and indoor vertical agriculture

- Maintains moisture and root support for crops without soil

Why Choose Closed Cell Over Open Cell Foam?

Compared to open cell foam, closed cell EVA foam offers:

- Higher Density and Strength – better for heavy-duty or structural use

- Superior Water Resistance – perfect for wet or outdoor environments

- Improved Insulation – resists heat, cold, and sound transfer

While open cell foam is softer and more breathable, closed cell foam excels in protection and durability.

Customization and OEM Services

Fubo provides full-service OEM customization for EVA foam products, including:

- Color, size, and hardness adjustments

- Custom molds, die cuts, and laminating

- Fire-retardant, UV-resistant, or anti-static options

- Bulk orders and international shipping

Whether you need branded packaging or unique foam shapes, Fubo works with clients from concept to delivery.

Environmental and Safety Considerations

- Fubo's EVA foams are non-toxic, odorless, and recyclable

- Products meet global safety standards for children, electronics, and food contact

- Production processes are energy-efficient and eco-conscious

Summary Table

| Product | Main Use | Key Features | Industries |

|---|---|---|---|

| Customized EVA Foam Inner Lining | Packaging for electronics, tools | Shock absorption, precision fit | Electronics, hardware, medical |

| EVA Foam Swimming Board | Swimming training | Buoyant, waterproof | Sports, education |

| EVA Toys with Numerical Letters | Educational toys | Soft, colorful, non-toxic | Children’s products |

| EVA Cushioning and Protective Material | Padding for helmets, braces | Flexible, durable, custom-cut | Medical, sports |

| Soilless Culture Foam Board | Hydroponic plant support | Moisture retention, root stability | Agriculture, horticulture |