Can EVA Foam Be Molded and Shaped? Exploring the Versatility of EVA Foam

2025-06-05

Table of Contents

- Introduction

- Understanding EVA Foam

- Can EVA Foam Be Molded and Shaped?

- Applications of Molded and Shaped EVA Foam

- Fubo's EVA Foam Solutions

- Summary: Key Takeaways

Introduction

EVA (Ethylene Vinyl Acetate) foam is a highly versatile material used in a wide range of industries due to its lightweight, durable, and flexible properties. It is particularly known for its ability to be molded and shaped to fit various applications. Whether used for cushioning, insulation, or shock absorption, EVA foam is an essential component in products ranging from electronics to sports equipment. But can EVA foam be molded and shaped? This article explores the answer to this question and the various applications of molded EVA foam, along with the solutions provided by Fubo, a leading foam manufacturer in China.

Understanding EVA Foam

Before diving into the molding and shaping process, it's essential to understand what EVA foam is and what makes it such a valuable material for a wide variety of industries.

What is EVA Foam?

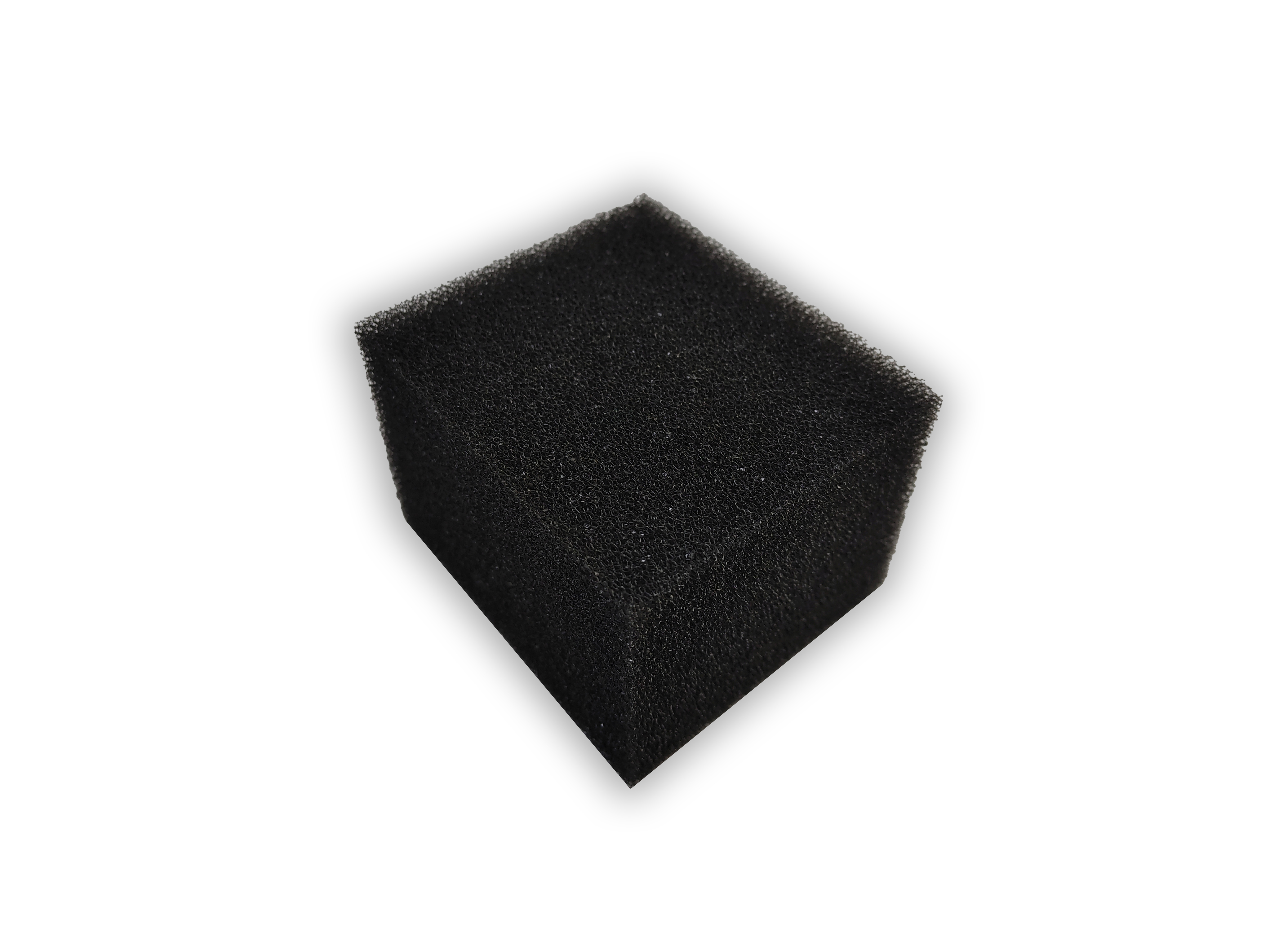

EVA foam is a lightweight, closed-cell foam material that combines ethylene and vinyl acetate. It is produced through a foaming process that results in a flexible, durable, and cushioned material. EVA foam is available in various densities and can be produced in different thicknesses, depending on its intended application.

Properties of EVA Foam

- Lightweight: EVA foam is lighter than many other materials, making it easy to handle and transport.

- Durability: It offers excellent durability and resistance to wear and tear, making it ideal for long-lasting applications.

- Shock Absorption: The foam's cushioning properties allow it to absorb shocks and impacts, which is useful in packaging and protective equipment.

- Non-Toxic and Safe: EVA foam is non-toxic and does not contain harmful chemicals, making it safe for various applications, including toys and swimming boards.

- Water Resistance: EVA foam is resistant to moisture, which makes it ideal for outdoor or water-based applications.

Can EVA Foam Be Molded and Shaped?

The short answer is yes, EVA foam can be molded and shaped. Thanks to its thermoplastic properties, EVA foam is highly adaptable and can be easily manipulated into various shapes and forms. The foam can be heated to a specific temperature where it becomes pliable, allowing it to be molded into custom shapes and sizes. Once it cools, the foam solidifies and retains its new form.

How Does EVA Foam Molding and Shaping Work?

The process of molding and shaping EVA foam involves several key steps:

- Heating: EVA foam is heated to a specific temperature, causing it to soften and become flexible.

- Shaping: Once softened, the foam can be shaped by applying pressure or using molds to create specific designs and patterns.

- Cooling: After shaping, the foam is cooled, which causes it to harden and retain its new form.

- Finishing: The molded foam can then be trimmed, cut, or further processed to meet the specific requirements of the application.

Factors Influencing Molding and Shaping

Several factors play a role in the molding and shaping process of EVA foam:

- Temperature: The temperature at which the EVA foam is heated is crucial in determining its flexibility and ease of shaping.

- Pressure: The amount of pressure applied during the molding process affects the final shape and consistency of the foam.

- Mold Design: The complexity of the mold used will determine the level of detail and accuracy in the final molded product.

Applications of Molded and Shaped EVA Foam

Due to its ability to be easily molded and shaped, EVA foam is used in a wide range of industries and products. Below are some of the most common applications:

1. Electronics and Appliances

In electronics, EVA foam is used for cushioning and shock absorption. Custom-molded EVA foam is often used as inner linings for packaging sensitive electronic devices, ensuring they are protected from impacts and vibrations during transportation.

2. Sports Equipment

EVA foam is used in sports equipment such as helmets, padding, and footwear. The material's shock-absorbing properties make it ideal for reducing impact and providing comfort during physical activities.

3. Drones

In the drone industry, EVA foam is used for protective casings and cushioning. Molded EVA foam is customized to fit specific parts of drones, protecting them from damage during transport or impact.

4. Packaging and Cushioning

Custom EVA foam is widely used for packaging fragile items such as glass, ceramics, and electronics. Its ability to be molded into specific shapes makes it an ideal material for providing custom cushioning solutions.

5. Toys and Educational Products

Children's toys, such as those with numerical letters and shapes, are often made from EVA foam. The foam is molded into various shapes and designs to create fun, safe, and educational products.

Fubo's EVA Foam Solutions

Fubo is a professional foam manufacturer located in Xiegang, Dongguan, Guangdong, China. We specialize in providing high-quality EVA foam solutions tailored to various industries, including electronics, appliances, sports equipment, and more. Some of our top EVA foam products include:

- Customized EVA Foam Inner Lining: Ideal for packaging electronics and appliances, providing custom cushioning solutions.

- EVA Foam Swimming Board: Lightweight and durable, designed for use in water activities.

- EVA Toys with Numerical Letters: Educational and safe toys for children, made from non-toxic EVA foam.

- EVA Cushioning and Protective Material: Custom foam solutions for protecting sensitive equipment during transport or storage.

- Soilless Culture Foam Board: Specialized foam for hydroponics and soilless farming applications.

Summary: Key Takeaways

In summary, EVA foam is a highly versatile material that can be molded and shaped into various forms for a wide range of applications. Its thermoplastic nature allows it to be easily manipulated, making it a valuable material in industries such as electronics, sports, packaging, and more. At Fubo, we provide high-quality EVA foam solutions that meet the needs of industries requiring custom molding and shaping capabilities.

Key Takeaways:

| Aspect | Details |

|---|---|

| Can EVA Foam Be M molded and Shaped? | Yes, EVA foam can be molded and shaped through heating, shaping, and cooling processes. |

| Key Applications | Electronics, sports equipment, packaging, toys, drones, and more. |

| Fubo's Offerings | Customized EVA foam inner linings, EVA swimming boards, EVA toys, cushioning materials, and soilless culture foam boards. |